In today’s fast-paced manufacturing and design industries, precision, speed, and quality are essential. Fiber laser marking machines have emerged as powerful tools that meet these needs, offering unmatched accuracy and durability for marking a wide range of materials. Whether you’re in the automotive, electronics, medical, or jewelry sectors, fiber lasers can significantly enhance your production capabilities. This guide explores everything you need to know about fiber laser marking machines—including how they work, benefits, applications, selection tips, and answers to the most frequently asked questions.

What is a Fiber Laser Marking Machine?

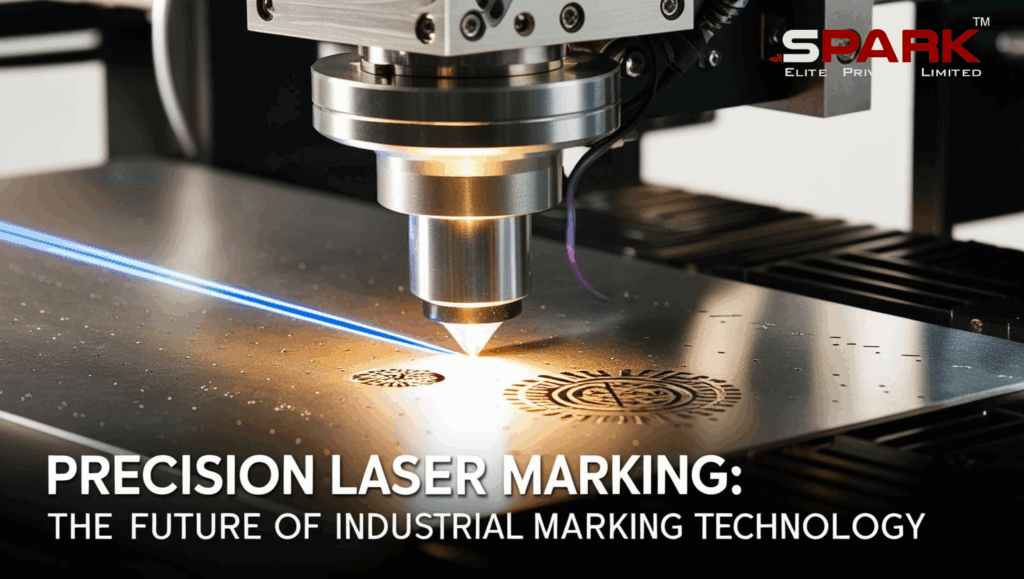

A fiber laser marking machine uses a highly focused beam of light generated by a fiber optic laser to create permanent marks on materials. These marks can include serial numbers, barcodes, QR codes, logos, graphics, and text. The process is non-contact, precise, and highly efficient.

Fiber lasers differ from other laser technologies, such as CO2 or UV lasers, due to their wavelength (typically 1064 nm), which is ideal for metals and some plastics.

How Fiber Lasers Work

The core of a fiber laser marking machine consists of:

- Laser Source: The source emits laser beams via a fiber optic cable.

- Galvanometer Scanning Head: Rapidly moves mirrors to direct the laser beam.

- F-Theta Lens: Focuses the laser onto the workpiece.

- Control Software: Allows users to import designs and set marking parameters.

The machine removes or alters the surface of a material using heat, resulting in high-contrast marks that are both permanent and resistant to wear.

Types of Fiber Laser Marking

1. Annealing

Creates color changes on metal surfaces without removing material.

2. Engraving

Removes material to create deeper marks.

3. Etching

Removes a thin layer of material.

4. Foaming

Used on plastics to create raised marks by melting the surface.

5. Carbon Migration

Used in stainless steel to create dark marks.

Key Features to Consider

- Laser Power: 20W, 30W, 50W, and higher for different applications.

- Marking Speed: Up to 7,000 mm/s, depending on the system.

- Resolution: Up to 0.001 mm for ultra-precise applications.

- Work Area: Common sizes include 100×100 mm, 200×200 mm, etc.

- Cooling System: Most fiber lasers are air-cooled, offering lower maintenance.

- Software Compatibility: EZCAD, LightBurn, or proprietary software.

- Rotary Axis: Optional feature for cylindrical objects.

Advantages of Fiber Laser Marking Machines

1. High Precision and Speed

Suitable for intricate designs and fast production lines.

2. Long Lifespan

Typically lasts 50,000–100,000 hours with minimal maintenance.

3. Cost-Effective

Low running costs due to high electrical efficiency and minimal consumables.

4. Versatility

Can mark metals, certain plastics, ceramics, and more.

5. Environmentally Friendly

No need for inks or chemicals.

6. Permanent Marking

Resistant to wear, corrosion, and high temperatures.

Common Applications

- Jewelry and Luxury Goods: Engraving serial numbers, logos, and intricate designs.

- Electronics: Marking PCBs, chips, and connectors.

- Medical Devices: UDI codes and part numbers.

- Automotive: VIN numbers, logos, component labeling.

- Aerospace: Part traceability and regulatory compliance.

- Tools and Hardware: Branding and measurements.

How to Use a Fiber Laser Marking Machine

Step-by-Step Guide:

- Setup: Place the machine on a stable surface and connect the power and computer.

- Install Software: Use the included USB drive or download from the manufacturer.

- Design Import: Load your graphics using EZCAD or compatible software.

- Material Placement: Fix the workpiece on the bed securely.

- Focus Adjustment: Use manual or auto-focus tools for best clarity.

- Parameter Setting: Adjust power, speed, frequency, and line spacing.

- Preview and Test: Check alignment using the “red light preview.”

- Start Marking: Run the marking job and monitor progress.

- Inspection: Examine the final output and perform post-processing if needed.

Maintenance Tips

- Daily: Clean the lens and surface area.

- Weekly: Check cables and connections.

- Monthly: Verify cooling system operation.

- Software Updates: Keep drivers and control programs current.

- Storage: Cover the machine when not in use to prevent dust accumulation.

Buying Guide

Key Factors:

- Application Type: What material and mark type do you need?

- Power Rating: 20W is good for basic marking; higher wattages for cutting and engraving.

- Work Area Size: Choose based on your product dimensions.

- Brand Reputation: Opt for manufacturers like Spark Elite with strong customer support.

- Warranty and Support: Minimum 1-year warranty with tech support.

Popular Models:

- Spark Elite FL-20 (Entry-level, 20W)

- Spark Elite FL-50 (High power, fast production)

FAQs

Q1: Can a fiber laser engrave and cut metal?

Yes, with appropriate power (usually 50W and above), fiber lasers can engrave and cut thin metal sheets.

Q2: What materials can be marked?

Common materials include gold, silver, stainless steel, brass, aluminum, titanium, and some plastics.

Q3: Is it safe to use at home?

Yes, with proper ventilation and safety precautions, desktop models are suitable for home workshops.

Q4: What’s the difference between CO2 and fiber lasers?

CO2 lasers are better for non-metals; fiber lasers are optimized for metal marking.

Q5: Do I need a chiller?

Most fiber lasers are air-cooled, so a chiller isn’t necessary unless specified.

Q6: How long do laser sources last?

Typically 50,000 to 100,000 hours.

Q7: Can I mark curved surfaces?

Yes, with a rotary attachment.

Q8: What file formats are supported?

Commonly supported: DXF, AI, PLT, BMP, JPG, and SVG.

Q9: Is fiber laser marking permanent?

Yes, it’s highly durable and resistant to wear, chemicals, and heat.

Q10: What is the maintenance cost?

Very low—mostly involves cleaning and occasional software updates.

Conclusion

A fiber laser marking machine is a smart investment for businesses that need high-quality, precise, and durable markings on a variety of materials. From industrial parts to luxury goods, these machines streamline production, enhance product identification, and open new creative possibilities.

Whether you’re upgrading your manufacturing line or starting a custom engraving business, choosing the right fiber laser can elevate your capabilities and offer substantial returns.

Explore trusted brands like Spark Elite for dependable performance, excellent support, and long-term value.

Precision meets productivity—unlock your potential with fiber laser technology.