Laser marking machines have revolutionized modern manufacturing, offering a fast, reliable, and high-precision method for marking or engraving parts and materials. From automotive and aerospace industries to medical device manufacturing and consumer electronics, laser marking is now a cornerstone of traceability, branding, and compliance.

In this guide, we’ll cover everything you need to know about laser marking machines, including how they work, their benefits, types, applications, and answers to frequently asked questions.

What is a Laser Marking Machine?

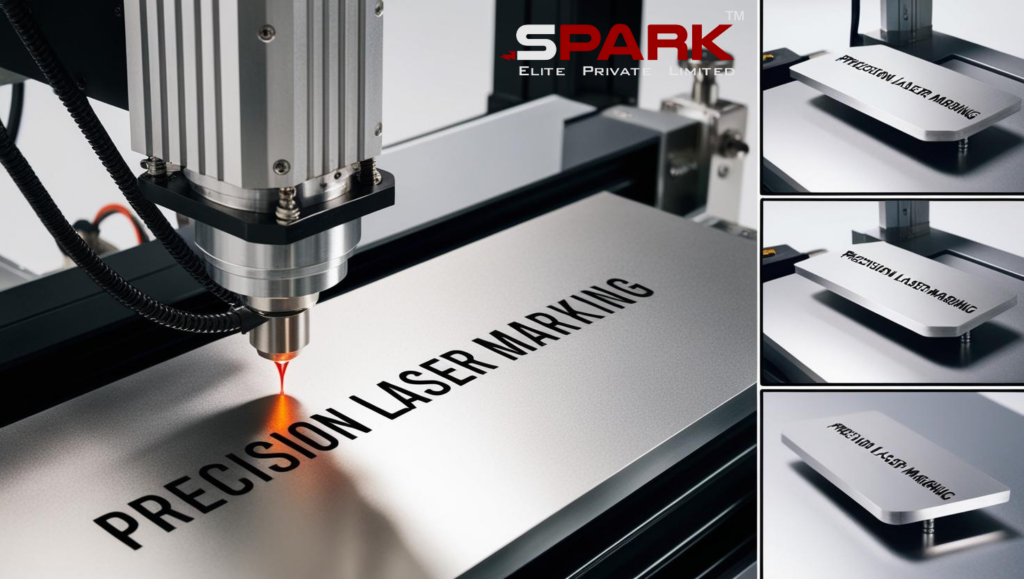

A laser marking machine is a device that uses a focused beam of light (laser) to mark or engrave a surface with text, logos, serial numbers, barcodes, or graphics. Unlike traditional printing or stamping methods, laser marking is non-contact and doesn’t involve consumables like ink or chemicals.

Laser marking can be used on a wide variety of materials, including:

- Metals (steel, aluminum, copper, brass)

- Plastics

- Ceramics

- Glass

- Wood

- Paper and cardboard

The technology is prized for its speed, accuracy, durability, and ability to produce high-resolution markings.

How Does Laser Marking Work?

Laser marking works by concentrating a high-energy light beam on a small area of the material surface. The laser’s heat alters the surface of the material to create visible markings. Depending on the type of laser and the material, this change may be due to:

- Oxidation (changing the surface color)

- Ablation (removing a thin layer of material)

- Foaming (raising material due to gas bubbles)

- Annealing (altering the crystal structure under the surface)

- Carbonization (burning the surface to darken it)

This process is managed by software that controls the laser’s path, intensity, speed, and pattern, allowing for customizable and repeatable designs.

Types of Laser Marking Machines

Laser marking machines come in several types based on the laser source used. Each type is suited to specific materials and applications.

1. Fiber Laser Marking Machines

- Best for: Metals, plastics

- Key Benefits: High precision, fast marking, long lifespan

- Applications: Automotive parts, tools, electronics, medical devices

Fiber lasers are the most popular choice due to their low maintenance, compact design, and high performance on metals.

2. CO₂ Laser Marking Machines

- Best for: Non-metallic materials like wood, leather, glass, paper, and acrylic

- Key Benefits: Cost-effective, good for organic materials

- Applications: Packaging, signage, promotional products, crafts

CO₂ lasers operate at a different wavelength than fiber lasers, making them ideal for organic or soft materials.

3. UV Laser Marking Machines

- Best for: Delicate materials (plastics, glass, silicon, PCB boards)

- Key Benefits: Cold marking with minimal heat damage

- Applications: Electronics, semiconductors, medical packaging

UV lasers use a low-power beam, making them perfect for high-precision tasks on sensitive surfaces.

4. Green Laser Marking Machines

- Best for: Highly reflective materials, transparent plastics

- Key Benefits: Low thermal impact

- Applications: Jewelry, glass marking, electronic parts

Green lasers provide better control for marking materials that are difficult to process with standard lasers.

Benefits of Laser Marking Machines

High Precision and Quality

Laser marking can produce extremely detailed and sharp markings, ideal for small components like microchips or medical tools.

Permanence

The marks created are resistant to wear, heat, and chemicals, making them ideal for industrial and long-lasting applications.

Non-Contact Process

There is no physical contact with the material, reducing the risk of damage or deformation.

No Consumables

Unlike inkjet printers or mechanical engraving, laser marking does not require inks, pastes, or cutting tools.

Environmentally Friendly

Laser marking reduces waste and emissions, making it a greener option compared to chemical etching or printing.

Cost-Efficient Over Time

While the upfront investment may be high, the lack of consumables and maintenance results in long-term savings.

Applications of Laser Marking Machines

Laser marking is used across countless industries for a wide range of applications. Here are some of the most common:

Automotive Industry

- Part identification and traceability

- VIN codes on components

- Branding logos

Medical Devices

- Marking of surgical tools and implants

- Compliance with FDA UDI regulations

Electronics

- Barcodes, QR codes, and serial numbers on PCBs and semiconductors

Jewelry and Luxury Goods

- Fine engraving of rings, watches, and accessories

Aerospace

- Marking parts for traceability and compliance

- Laser-engraved data matrix codes

Consumer Products

- Branding and customization on items like pens, keychains, and mugs

Packaging Industry

Date codes, batch numbers, and barcodes on labels or packages

Choosing the Right Laser Marking Machine

When selecting a laser marking machine, consider the following factors:

Budget – Upfront cost vs. long-term ROI

Material – What materials will you mark most frequently?

Marking Depth & Resolution – Do you need surface-level marks or deep engravings?

Speed – What’s the production rate or batch size?

Environment – Will it be used in a factory, lab, or office setting?

Software Compatibility – Does it integrate with your design and inventory systems?

Maintenance and Safety

Laser marking machines require minimal maintenance but should be operated with safety in mind:

Regular calibration ensures optimal performance and consistency.

Enclosures and safety shields prevent accidental exposure to the laser beam.

Exhaust systems help remove fumes, especially when marking plastics or organic materials.

Protective eyewear is essential when working with open laser systems.

Future of Laser Marking

As manufacturing continues to adopt Industry 4.0 principles, laser marking will play a key role in automation and smart factories. Integration with robotic arms, machine vision, and AI-powered quality checks will further increase speed and reliability.

New laser sources like femtosecond and picosecond lasers are also emerging, offering even higher precision for microfabrication and nanotechnology.

Frequently Asked Questions (FAQ)

What’s the difference between laser marking, engraving, and etching?

- Marking: Changes the surface appearance without removing material.

- Engraving: Removes a portion of material to create a deep mark.

- Etching: A subset of engraving that typically uses chemical processes or lower power lasers to create shallow marks.

Can a laser marking machine work on all materials?

Not all machines work on all materials. For example:

- Fiber lasers are ideal for metals and some plastics.

- CO₂ lasers are better for wood, leather, and acrylic.

- UV lasers work well with sensitive materials like glass or silicone.

Is laser marking permanent?

Yes. Laser marks are resistant to abrasion, heat, and chemicals, making them suitable for long-term applications, especially in industrial settings.

What industries use laser marking the most?

- Automotive

- Aerospace

- Medical

- Electronics

- Jewelry

- Packaging

How fast is laser marking compared to traditional methods?

Laser marking is significantly faster, especially for high-volume or automated production lines. Some systems can mark hundreds of parts per minute depending on complexity.

Is laser marking environmentally friendly?

Yes. It doesn’t use ink, solvents, or other consumables, and produces minimal waste or emissions.

How long does a laser marking machine last?

A well-maintained fiber laser machine can last over 100,000 hours, making it a great long-term investment.

Can I use one laser for different materials?

While some high-end systems support multi-material marking, most machines are optimized for specific materials. You may need different machines for metals vs. plastics vs. organics.

Do I need a license to operate a laser marking machine?

Generally, you don’t need a license in the U.S., but operators must follow OSHA and ANSI safety guidelines, and training is strongly recommended.

How much does a laser marking machine cost?

Prices vary based on type and power:

- Entry-level CO₂ lasers: $2,000 – $5,000

- Mid-range fiber lasers: $7,000 – $20,000

- Industrial UV or femtosecond lasers: $25,000 – $100,000+

Conclusion

Laser marking machines are a game-changing tool in modern manufacturing and product customization. They offer high-quality, permanent, and eco-friendly marking solutions across a wide range of materials and industries.

Whether you’re a small business owner looking to customize products or a large manufacturer needing traceability and compliance, there’s a laser marking machine that fits your needs.

Want help choosing the right machine or setting up your laser marking operation? Just ask!