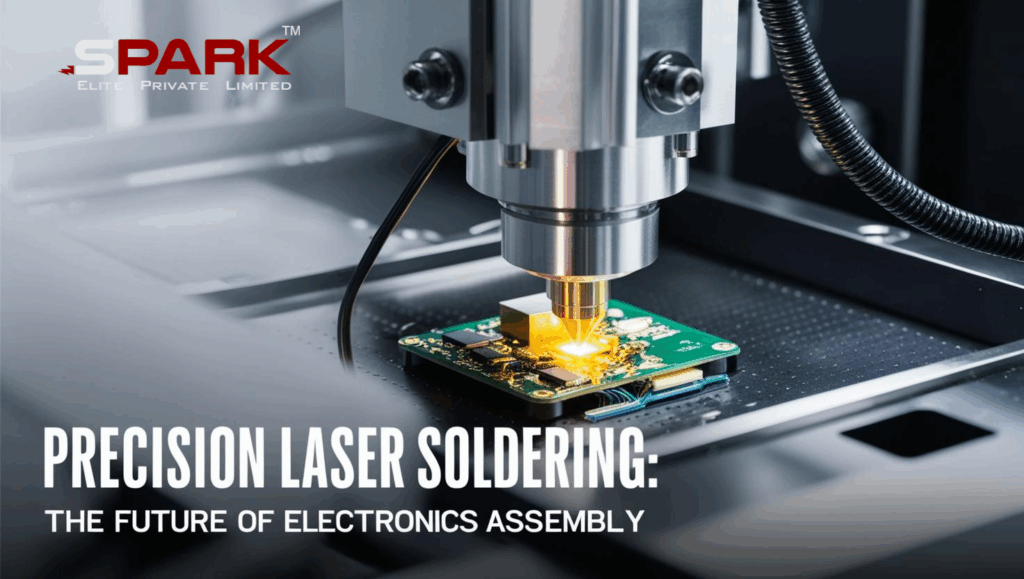

A laser soldering machine represents a cutting-edge advancement in precision electronics assembly and metal joining. Using a focused laser beam, these machines apply heat to melt solder and form secure, clean connections between components. Laser soldering offers a high degree of control, making it ideal for microelectronics, PCBs, and delicate components that may be damaged by traditional soldering methods.

What is a Laser Soldering Machine?

A laser soldering machine is a specialized tool that uses a laser beam—usually a fiber or diode laser—to melt solder and join components together. Unlike traditional soldering tools like soldering irons or wave soldering machines, laser soldering is contactless and highly localized, reducing the risk of thermal damage and contamination.

Key Features of Laser Soldering Machines

- Precision Heating: Targeted laser beam allows for soldering of microscopic components.

- Non-Contact Operation: Prevents mechanical stress and surface damage.

- Minimal Thermal Impact: Protects temperature-sensitive components.

- Consistent Results: Ideal for automated and batch production lines.

- Real-Time Monitoring: Some systems come with cameras and sensors for quality control.

- Programmable Settings: Easily configurable for various solder types and applications.

Advantages of Laser Soldering

- No Physical Contact: Reduces wear and tear on tools and components.

- High Repeatability: Consistent soldering quality across large batches.

- Reduced Maintenance: Fewer moving parts compared to traditional equipment.

- Fast Heating/Cooling Cycle: Minimizes thermal stress.

- Suitable for Fine-Pitch Components: Excellent for modern high-density PCBs.

Common Applications

1. Electronics Manufacturing

- Soldering components on circuit boards

- Reflow soldering for SMDs

2. Medical Devices

- Assembly of sensors and compact circuitry

- No contamination from flux

3. Automotive Electronics

- Joining sensors and microcontrollers

4. Aerospace and Defense

- High-reliability solder joints for critical systems

5. Consumer Electronics

- Camera modules, smartphones, and wearables

Types of Laser Soldering Systems

1. Manual Systems

- Suitable for prototyping and low-volume work

2. Semi-Automatic Systems

- Operator assisted but with some automation

3. Fully Automatic Systems

- For high-speed, large-volume production lines

Components of a Laser Soldering Machine

- Laser Source (Diode or Fiber)

- Beam Delivery System (Optical fibers and focusing lens)

- Control Unit (Software and electronics)

- Cooling System

- Vision System (Cameras for alignment and quality check)

- Solder Feeder (Optional in automated models)

Working Principle

- Design and Programming: Load CAD or soldering pattern into the control software.

- Component Placement: Position workpiece and secure it.

- Laser Activation: Laser beam melts the solder at the exact joint location.

- Joint Formation: Solder solidifies, forming a strong bond.

- Quality Check: Some systems include AOI (Automated Optical Inspection).

How to Choose the Right Machine

- Laser Type and Power: Choose based on material and solder type.

- Precision Needs: Higher precision for microelectronics.

- Volume of Production: Manual for low, automatic for high-volume.

- Budget: Entry-level systems vs. industrial-grade solutions.

- Software Features: Look for customization and automation support.

- After-Sales Support: Critical for troubleshooting and upgrades.

Installation and Setup

- Place on Stable Surface: In a clean, ESD-safe environment.

- Connect Power and Cooling: Set up water or air cooling.

- Software Installation: Load machine control software.

- Calibration: Align the laser and test with sample components.

- Safety Precautions: Ensure protective eyewear and enclosures are used.

Maintenance Guidelines

- Clean optics and lens regularly

- Replace filters in cooling systems

- Update firmware/software

- Inspect beam alignment

- Ensure solder feed systems (if present) are unclogged

Safety Considerations

- Use laser-safe enclosures or goggles

- Ensure ventilation for fume extraction

- Follow workplace laser safety standards (e.g., ANSI Z136)

- Train operators thoroughly

Pricing and ROI

- Entry-level Systems: Start at $10,000

- Mid-range: $20,000 – $50,000

- High-End Automated Systems: $75,000 and up

The long-term benefits—reduced labor, improved quality, and faster production—ensure a solid return on investment.

Frequently Asked Questions (FAQ)

Q1: Can laser soldering machines be used for lead-free solder?

Yes, they are compatible with both leaded and lead-free solders.

Q2: What types of lasers are commonly used?

Diode and fiber lasers are the most common.

Q3: Do I need special training to operate one?

Basic training is usually sufficient, especially for semi-automated systems.

Q4: How accurate are laser soldering machines?

Accuracy can reach micrometer levels, depending on the system.

Q5: What materials can be soldered?

Most common metals like copper, gold, silver, tin, and alloys.

Q6: Can I solder multilayer PCBs?

Yes, with proper settings and component alignment.

Q7: Is flux required?

Not always. Many systems allow flux-free soldering to avoid contamination.

Q8: Are they suitable for small businesses?

Yes, especially manual or semi-automatic systems.

Q9: What is the lifespan of a laser soldering machine?

Typically 8–10 years with regular maintenance.

Q10: Can I integrate it with my existing production line?

Yes, most automated systems can be customized for inline production.

Conclusion

Laser soldering machines offer a state-of-the-art solution for precise, clean, and reliable solder joints in today’s high-tech industries. From medical devices to aerospace systems, their versatility and efficiency make them a smart investment.

By choosing the right machine and maintaining it properly, you can achieve superior soldering quality, higher production yields, and a quicker return on investment. Whether you’re a large-scale manufacturer or a startup focused on electronics assembly, laser soldering is a future-proof technology that enhances both product quality and operational efficiency.